Ferroelectric Random-Access Memory (FRAM) is a non-volatile memory technology that combines the speed of RAM with the persistence of flash memory. Unlike traditional storage solutions, FRAM leverages the unique properties of ferroelectric materials to deliver high endurance, fast write speeds, and low power consumption. This guide explores FRAM’s workings, applications, advantages, and future potential.

Table of Contents

ToggleHow FRAM Works

The Ferroelectric Effect

FRAM relies on ferroelectric materials, such as lead zirconate titanate (PZT) or strontium bismuth tantalate (SBT). These materials exhibit a reversible electric polarization when exposed to an electric field. The polarization state (up or down) represents binary data (0 or 1) and persists without power, enabling non-volatility.

Memory Cell Structure

A FRAM cell consists of a 1T1C structure: one transistor and one ferroelectric capacitor. The transistor controls access to the capacitor, which stores the polarization state. This design is similar to DRAM but replaces the dielectric capacitor with a ferroelectric one.

Read/Write Operations

- Write: Applying a voltage switches the capacitor’s polarization. This process is fast (~100 ns) and requires minimal energy.

- Read: Measuring the capacitor’s charge detects the polarization state. Modern FRAMs automatically restore data after reads to prevent disturbance, ensuring high endurance.

Comparison with Other Memory Technologies

| Feature | FRAM | EEPROM/Flash | SRAM | DRAM |

|---|---|---|---|---|

| Volatility | Non-Volatile | Non-Volatile | Volatile | Volatile |

| Endurance | 1e14 cycles | 1e4–1e5 | Unlimited | Unlimited |

| Write Speed | ~100 ns | ~1–10 ms | ~10 ns | ~10 ns |

| Power | Low | High (charge pump) | Moderate | Moderate |

| Density | Low-Moderate | High | Low | High |

| Cost | High | Low | High | Moderate |

Key Advantages of FRAM:

- High Endurance: Suitable for frequent data logging (e.g., smart meters).

- Byte-Level Writes: No block erasure required, unlike flash.

- Low Power: Ideal for battery-powered IoT devices.

Limitations:

- Higher cost per bit compared to flash.

- Limited density (typically ≤ 4 Mb).

Applications of FRAM

- Industrial Automation: Stores calibration data and event logs in harsh environments.

- Automotive: Used in ECUs, black boxes, and infotainment systems for reliable data retention.

- Medical Devices: Ensures longevity in implantable devices like pacemakers.

- Smart Meters: Tracks energy usage with high write cycles.

- Consumer Electronics: RFID tags, gaming consoles, and wearables benefit from fast writes.

Historical Development

FRAM was first researched in the 1980s, with commercialization in the 1990s by companies like Ramtron (now part of Infineon). Early challenges included integrating ferroelectric materials with CMOS processes. Advances in material science and manufacturing have since improved scalability and reliability.

Technical Specifications

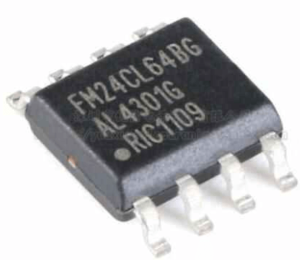

- Density: Ranges from 4 Kb to 4 Mb (e.g., Infineon’s CY15B104Q).

- Interfaces: SPI, I2C, and parallel interfaces.

- Voltage: 1.8V–5.5V operation.

- Temperature: Industrial-grade options (-40°C to +85°C) and automotive-grade (-40°C to +125°C).

Challenges and Limitations

- Material Costs: PZT contains lead, raising environmental concerns. SBT is lead-free but less common.

- Scalability: Competing with emerging memories like MRAM and RRAM.

- Data Retention: High temperatures may reduce retention time, though modern FRAMs guarantee 10+ years at 85°C.

Future Trends

- Advanced Materials: Lead-free ferroelectrics and 3D stacking for higher density.

- IoT Integration: Ultra-low-power FRAM for edge devices.

- AI/Edge Computing: In-memory computing architectures leveraging FRAM’s speed.

- Automotive Growth: Adoption in electric vehicles for real-time data logging.

Leading Manufacturers

- Infineon: CY15 series (SPI/I2C interfaces).

- Fujitsu: MB85RC family (high-temperature variants).

- Texas Instruments: Integrated FRAM in MSP430 microcontrollers.

Design Considerations

- Interface Selection: SPI for speed, I2C for simplicity.

- Power Management : Leverage FRAM’s low active current ( e.g., 150 µA/MHz).

- Data Retention: Use ECC in critical applications to mitigate bit errors.

Conclusion

FRAM fills a unique niche in the memory landscape, offering unparalleled endurance and speed for applications requiring frequent, reliable writes. While challenges like cost persist, ongoing advancements in materials and integration herald a promising future. As IoT and automotive industries expand, FRAM is poised to play a pivotal role in next-generation electronics.

Further Reading: Explore datasheets from Infineon and Fujitsu for technical details, or research papers on ferroelectric materials for deeper insights into FRAM’s evolving technology.

- Everything You Need To Know About Limit Switch - May 21, 2025

- Everthing You Should Know About Rheostat - May 20, 2025

- Everything You Need To Know About Reversing Contactor - May 19, 2025