A latching relay is an electromechanical switch that maintains its contact position after the actuating power is removed, distinguishing it from standard relays that require continuous power to remain engaged. This unique feature makes latching relays ideal for energy-efficient applications and scenarios where state retention is critical, even during power outages.

How Latching Relays Work

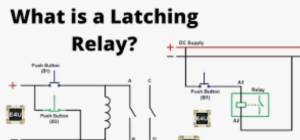

Latching relays utilize a bistable mechanism, allowing them to stay in their last switched position without power. They achieve this through two primary designs:

Magnetic Latching Relays: Incorporate a permanent magnet. A short pulse to the coil generates a magnetic field that either aligns with or opposes the permanent magnet, switching the contact. Reversing the coil’s polarity resets the state.

Mechanical Latching Relays: Use a physical mechanism, such as a spring or lever, to lock contacts in place until another pulse releases them.

Coil Configurations

Single-Coil: Requires polarity reversal to switch states, often using an H-bridge circuit.

Dual-Coil: Features separate “set” and “reset” coils, each activated by a unidirectional pulse.

Types of Latching Relays

Bistable Relays: Synonymous with latching relays, offering two stable states.

Contact Configurations: Available in SPDT (Single Pole Double Throw), DPDT (Double Pole Double Throw), and more, catering to diverse circuit needs.

Applications

Energy-Efficient Systems: Battery-operated devices, smart meters, and solar power systems.

Automotive: Memory seats, power windows.

Industrial Automation: Machinery requiring state retention post-power loss.

Telecommunications: Network switches and routing equipment.

Advantages

Low Power Consumption: Only requires energy during switching.

State Retention: Maintains position during power outages.

Reduced Heat Generation: Enhances longevity and reliability.

Disadvantages

Complex Control Circuitry: Needs polarity reversal (single-coil) or dual circuits.

Higher Cost: More intricate design than standard relays.

Potential for Stuck States: Incorrect pulses may leave contacts in unintended positions.

Selection Criteria

Electrical Ratings: Voltage/current capacity of contacts and coil.

Coil Type: Single-coil (simpler wiring) vs. dual-coil (easier control).

Environmental Conditions: Temperature, humidity, and vibration resistance.

Certifications: Compliance with UL, CE, or industry-specific standards.

Switching Speed and Lifespan: Critical for high-frequency applications.

Installation and Maintenance Tips

Polarity Awareness: Ensure correct polarity for single-coil types to avoid damage.

Surge Protection: Use diodes or suppressors to protect coils from voltage spikes.

Testing: Verify functionality with a multimeter post-installation.

Maintenance: Periodically check contacts for wear or corrosion.

Future Trends

Miniaturization: Compact designs for portable electronics.

Smart Integration: IoT-enabled relays with embedded diagnostics.

Solid-State Hybrids: Combining durability of solid-state with latching efficiency.

Conclusion

Latching relays are pivotal in modern electronics, offering efficiency and reliability. Understanding their operation, types, and applications ensures optimal selection and implementation. As technology advances, their role in energy conservation and smart systems will expand, driving innovation in design and functionality.

- Everything You Need To Know About Limit Switch - May 21, 2025

- Everthing You Should Know About Rheostat - May 20, 2025

- Everything You Need To Know About Reversing Contactor - May 19, 2025