Integrated Circuit ( IC) batteries represent a fusion of energy storage and advanced electronics, designed to enhance performance, safety, and efficiency. These batteries incorporate a dedicated IC to manage critical functions such as charging, discharging, and thermal regulation. Widely used in consumer electronics, electric vehicles (EVs), and medical devices, IC batteries are pivotal in modern technology. This guide explores their structure, types, applications, and future trends.

Table of Contents

ToggleWhat Are IC Batteries?

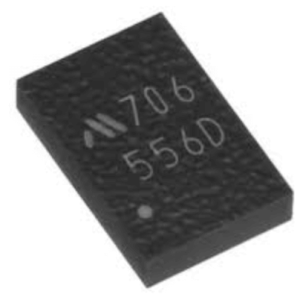

An IC battery integrates a battery cell (typically lithium-ion or lithium-polymer) with a management IC. This IC acts as a safeguard, monitoring voltage, current, and temperature to prevent hazards like overcharging or thermal runaway. Unlike standard batteries, IC batteries actively communicate with devices to optimize performance and lifespan.

Structure of IC Batteries

- Battery Cell: The core energy storage unit, often using lithium-based chemistry for high energy density.

- Protection IC: A microcontroller that oversees:

- Voltage Regulation: Prevents overcharge (>4.2V/cell) and over-discharge (<2.5V/cell).

- Current Control: Limits excessive current flow during charging/discharging.

- Thermal Management: Monitors temperature via sensors and triggers shutdown if thresholds are exceeded.

- Communication Interface: Advanced ICs use protocols like SMBus or I²C to relay data ( e.g., state of charge) to the host device.

- Peripheral Components : Includes MOSFETs for circuit switching, resistors, and capacitors for signal conditioning.

Types of IC Batteries

- By Chemistry:

- Lithium-ion (Li-ion): High energy density, common in smartphones and laptops.

- Lithium-Polymer (LiPo): Flexible form factors, used in drones and wearables.

- Nickel-Metal Hydride (NiMH): Lower cost, found in medical devices and backup systems.

- By Application:

- Single-Cell: Small devices (e.g., wireless earbuds) with basic voltage protection.

- Multi-Cell Packs: EVs and power tools requiring complex Battery Management Systems (BMS) for cell balancing and state-of-health monitoring.

How IC Batteries Work

The IC performs real-time monitoring and control:

- Charging Phase:

- Constant Current (CC): Delivers maximum current until voltage peaks.

- Constant Voltage (CV): Maintains peak voltage while tapering current.

- Termination: Cuts off at 5-10% of initial current to prevent overcharge.

- Discharging Phase:

- Blocks discharge if voltage drops below a safe threshold (e.g., 2.7V for Li-ion).

- Fault Handling:

- Triggers failsafes for short circuits, overheating, or overcurrent.

- Cell Balancing:

- In multi-cell setups, redistributes charge to ensure uniformity.

Applications of IC Batteries

- Consumer Electronics: Smartphones, laptops, and tablets rely on ICs for safe fast charging.

- Electric Vehicles: High-power BMS manage 100+ cells, optimizing range and longevity.

- Medical Devices: Implants and portable equipment demand ultra-reliable power with fail-safes.

- Renewable Energy: Solar storage systems use ICs for efficient energy harvesting.

- IoT: Sensors and wearables benefit from compact, self-monitoring batteries.

Advantages and Disadvantages

Pros:

- Enhanced Safety: Prevents explosions and leaks.

- Longer Lifespan: Reduces degradation via precise management.

- Efficiency: Minimizes energy waste during charge cycles.

Cons:

- Cost: Adds 10-20% to battery price.

- Size Constraints: ICs require additional PCB space.

- Complexity: Failure in the IC can disable the entire battery.

Safety Considerations

- Protections: Overvoltage, undervoltage, overcurrent, short circuit, and thermal shutdown.

- Certifications: UL 2054, IEC 62133, and UN/DOT 38.3 ensure compliance with safety standards.

- Thermal Runaway Mitigation: Advanced ICs detect pressure changes and gas buildup.

Future Trends

- Solid-State Batteries: Safer, higher-capacity alternatives with integrated ICs.

- AI-Driven BMS: Machine learning predicts battery health and optimizes cycles.

- Sustainability: Recyclable designs and second-life applications for EV batteries.

- Fast-Charging ICs: Gallium nitride (GaN) tech enabling 10-minute EV charges.

Conclusion

IC batteries are the cornerstone of modern portable power, merging robust energy storage with intelligent management. As technology advances, their role in EVs, renewable energy, and IoT will expand, driven by innovations in safety and sustainability. Understanding their workings and applications empowers consumers and engineers to harness their full potential.

FAQs

- Can IC batteries be repaired?

ICs are not user-serviceable; replacement is recommended if faults occur. - Do all lithium batteries have ICs?

Most consumer-grade Li-ion batteries include ICs, but industrial cells may omit them for custom BMS. - How long do IC batteries last?

Typically 300-500 cycles (2-3 years), depending on usage and management. - Are IC batteries recyclable?

Yes, but specialized facilities are required to handle IC components safely.

By integrating cutting-edge electronics with energy storage, IC batteries continue to revolutionize industries, balancing performance with protection. Stay informed to leverage their benefits in your next project or purchase.

- Everything You Need To Know About Limit Switch - May 21, 2025

- Everthing You Should Know About Rheostat - May 20, 2025

- Everything You Need To Know About Reversing Contactor - May 19, 2025